Galileo CupWheel – Field Test Results

- Dec 28, 2023

- 4 min read

Updated: Oct 14, 2024

The influence of using CupWheel on field traction was conducted by IPW from Germany in October 2013 (with the Mitas R&D team). The tests were conducted in DAULA Germany, on a sandy surface. The breaking tractor was large MASSEY FERGUSON. A difference in tractive force of < 30% in favor of the CupWheel (270/70CW18) was Measured.

Dependence of pulling force on tire slippage (a) CupWheel (270/70CW18), (b) (270/70CW18)

Better traction for enhanced efficiency and energy savings

Field tests were conducted in Europe on July 22, 2015 by the Research Institute of Agricultural Engineering*. The surface consisted of a barley stubble field ploughed by a disc harrow to a depth of 120 mm. A John Deere 6150R tractor mounted with the CupWheel 480/65R28 on the front axle and the CupWheel 600/65G38 on the rear axle. The performance of three types of tires were compared. The CupWheel slippage and traction forces were measured using several driving modes.

The results show that the traction force of CupWheel 600/65R38CW is approximately 25% higher than a standard tire and that the CupWheel delivers approximately 15% more traction than an IF tire. The 480/65R28CW, it has an approximate 10% advantage in traction force over a standard tire, and an approximate 7% over the IF tire.

Experimental Measured Results

IF tire | VF tire | CupWheel | Improvement %* | |

Inflation pressure, kPa | 160 | 100 | 60 | 37.5 |

Deflection, mm | 102 | 140 | 152 | 149.0 |

Footprint, cm2 | 2584 | 3299 | 3557 | 137.7 |

Ground pressure, kPa | 139 | 108 | 101 | 72.7 |

Lateral stiffness | 19 | 31 | 65 | 342.1 |

*100% refers to Ref. IF tire

Galileo CupWheel was recently tested by the editors of Boerderij together with experts from Aeres Hogeschool in Dronten. The measurements were carried out by independent research institute CREA. The results were published on “Future Farming” magazine, Feb. 2019 (Research institute CREA, “Future Farming” magazine, Feb. 2019). The test was performed on stony soil that consisted of clay (6.4%) and sand (47.1%). The test measurements were carried out during motion using an 8.2ton John Deere 7530, while the braking vehicle was a Same Galaxy 170 carrying measuring equipment. Traction at various slippage percentages was tested.

The difference in tractive force between conventional tiers and the CupWheel is greatest at between 20-30% slippage. On average, over all of these measurements, the difference in tractive force of 17.6% is in favor of the CupWheel. According to the researchers of CREA testing institute, you could directly convert that increase of 17.6% into a fuel saving and/or time saving. The CupWheel behavior is smooth, flat contact surface with the ground, regardless of the tire pressure.

Enhanced lateral stability for improved steering and slope performance

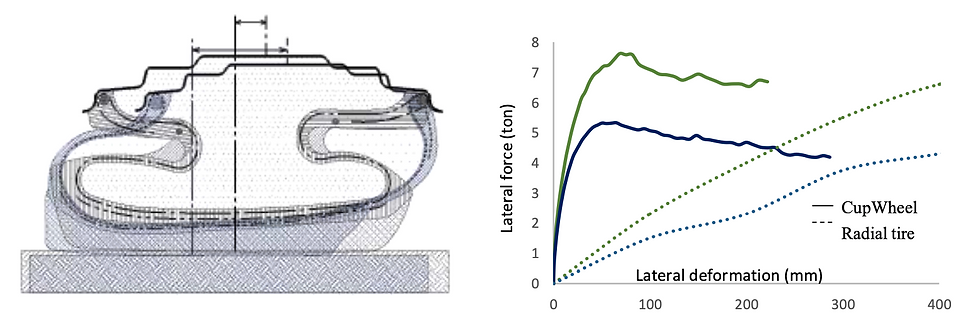

The lateral stability of the CupWheel is significantly improved compared to a standard tire with low air pressure and high load conditions. The CupWheel's lateral stiffness curve is steep at the beginning until the tire starts to slip (the earlier the better). When no more force can be delivered, the curve straightens out. This is unlike the standard tire (mainly with low air pressure) where the tire tends to bend (and not slip), limiting the lateral stability forces.

Testing has demonstrated 167% higher lateral stability than a standard tire (TREKKER DECEMBER 2018 , Test: bandrups vs. radiaalband, TRACTIE EN STABILITEIT). Measured lateral stiffness: 15 and 40 daN/mm for 280/70R18 at 1.6bar and 280/70CW18 at 0.8 bar, respectably.

Typical lateral deformation and force generation vs. lateral deformation, various inflation pressures

Improved ride comfort and safety

The CupWheel ensures stable driving even with low inflation pressures, ensuring ride comfort and safety. According to TREKKER DECEMBER testing (TREKKER DECEMBER 2018 , Test: bandrups vs. radiaalband, TRACTIE EN STABILITEIT) performed on 2018,

“We mainly experience more grip and more stability, especially when we turn at the headlands on a sloping slope. With standard tires sometimes we dare not, but with the CupWheel underneath, you can go through much longer you stand more stable. It really gives a safe feeling”.

Larger footprint with uniform load distribution

As air pressure decreases, the CupWheel footprint increases monotonically. Traditional tire technologies (both bias and radial) do not allow for consistent ground contact in cases of low air pressure due to the tire structure. In such cases, the tires begin to buckle inwards, leading to inefficient operations and increased ground compaction along the sides where the pressure is being diverted to.

Footprint with Equal Load and Low Inflation Pressure: (a) “Cup-Wheel” (b)

Compared to traditional tire, the CupWheel footprint is longer and presents an equal distribution surface area. As a tire's performance is significantly influenced by the shape of its contact patch/footprint, the unique CupWheel footprint delivers enhanced performance characteristics. Tests conducted on CupWheel on 38" and 18” tiers by Mitas on 2013, demonstrated the clear significantly larger footprint advantages of CupWheel, +53% compared with the ref. radial tire.

Comments